Active Roster

Media

Sponsors

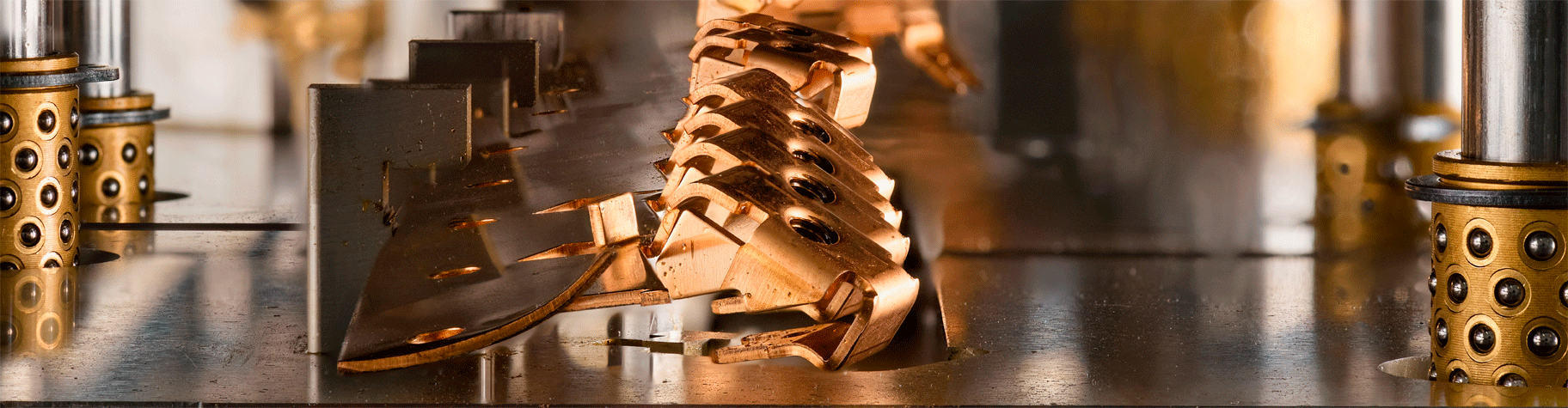

Stamping technology

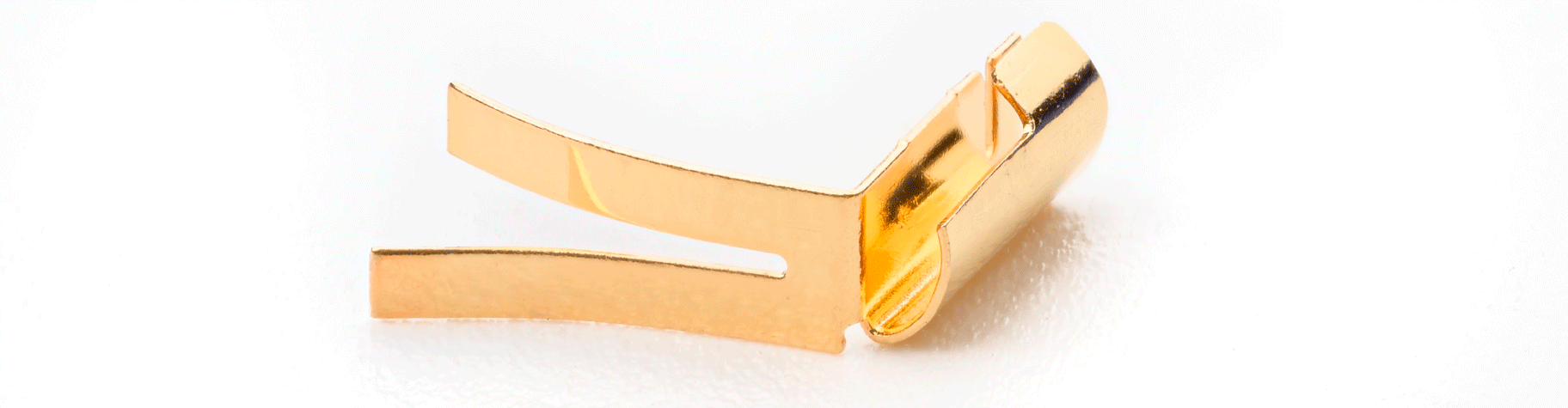

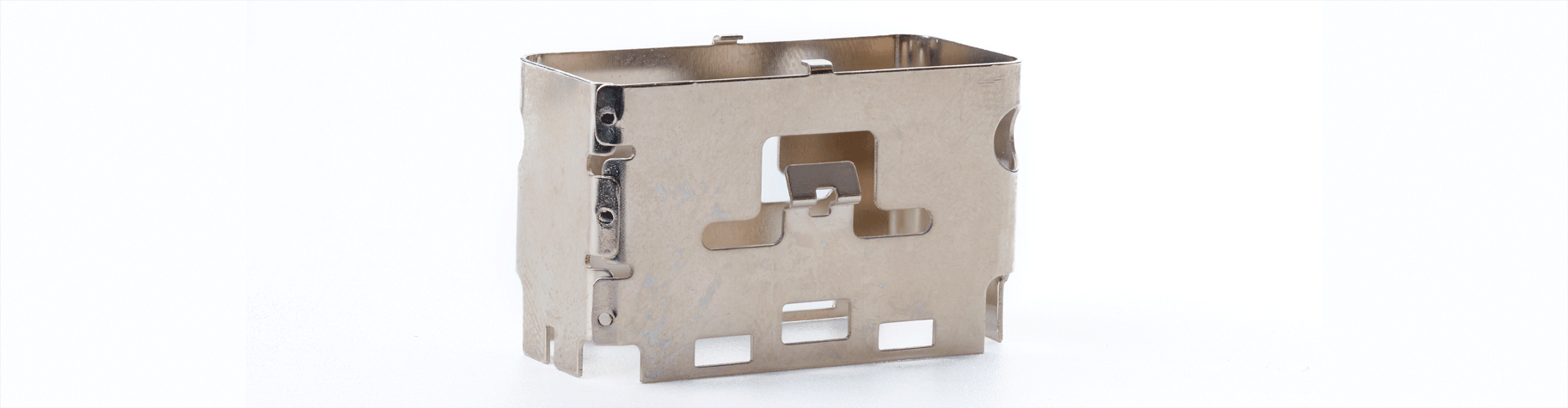

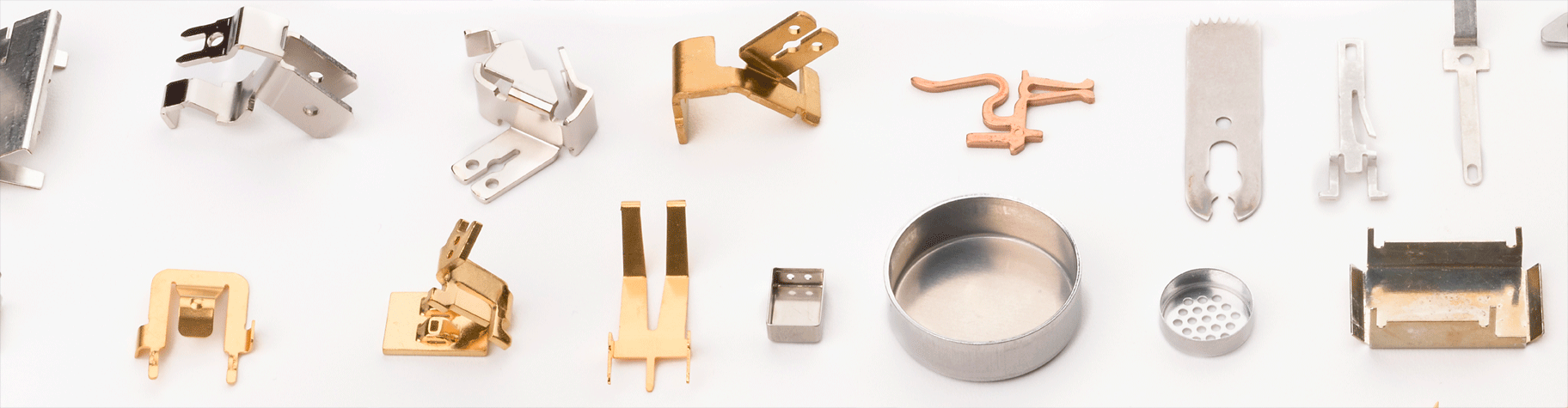

Product range

Using pressures of up to 51 tonnes, we manufacture stamped parts between 0.05 and 4 mm thickness with either progressive, forming or compound dies, depending on the material and requirements.

Innovative process technologies

We employ innovative process technologies for the variable production of stamped and formed parts from steel strip. In combination with our special tooling technology, we are able to produce complete families of products with basic tools and custom attachments. Depending on the specification for the individual parts, our manufacturing processes can combine stamping, forming and deep-drawing.

In order to ensure maximum production efficiency, our engineering services staff carry out feasibility studies and discuss in detail which production steps need to be undertaken and in which order, which material is to be used and what tolerances are required. This enables us to carry out high-volume series production while being able to accept smaller production quantities of just a few hundred units.

Very cost-effective series production

Let us produce for you. We can adjust our stamping tools to work at fast speeds, making series production very cost-effective. Depending on the parts geometry and tool design, our machines can operate at up to 1,000 strokes per minute.

Very small to big production quantities

Large production quantities of 100 million parts per year are not unusual, medium quantities of between 20 and 30 million parts are the norm. We also have a very cost-effective production capability for small and very small production runs: depending on the material and geometry specifications, we can produce quantities starting from just a few hundred parts. All at very acceptable prices for the customer.

We'd love to hear from you

so we can find the best solution for you