Active Roster

Media

Sponsors

Thrust bearing solutions

Custom axial deep groove ball bearings

Every project has its own specific requirements. That’s why our axial deep groove ball bearings are designed to customer specifications and for various industries.

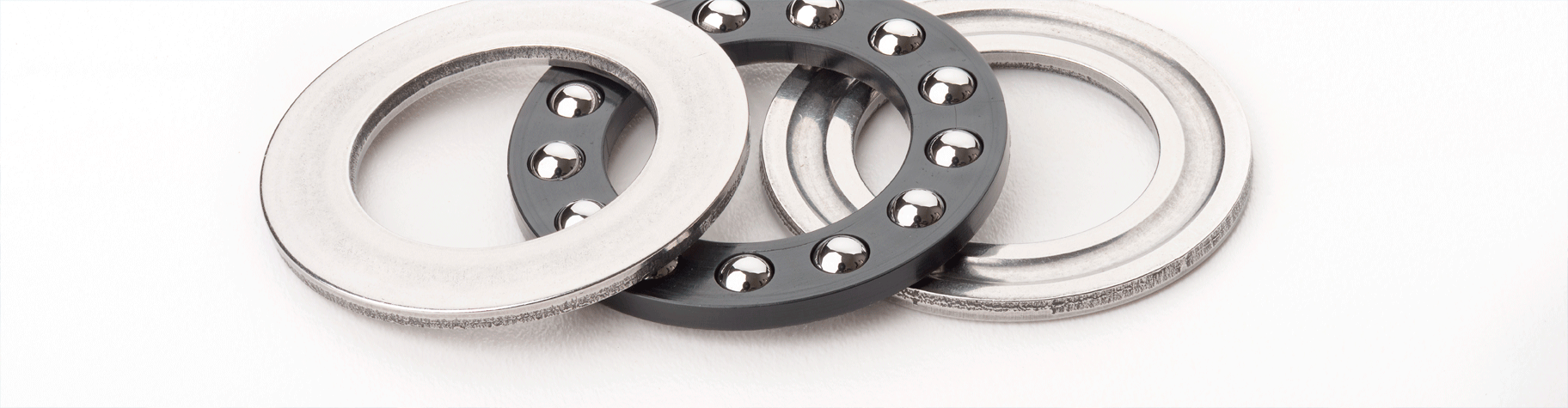

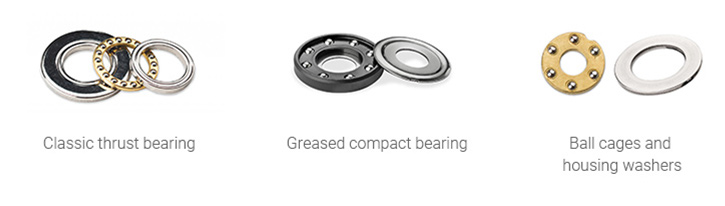

Classic Bearings

The Classic Bearing is a loose set of 2 grooved discs and a ball cage with balls. The client is responsible for its final assembly and greasing.

This thrust bearing is very flexible. For example, you can choose discs in two different sizes and from different materials, so that you get the optimal bearing for your project.

Compact Bearings

The compact bearing is designed according to customer requirements, manufactured by us, assembled, greased (lifetime lubrication) and 100% tested. This means you receive a maintenance-free thrust bearing which, thanks to its compact design, fits perfectly into narrow spaces.

But the biggest advantage for you is certainly the easy handling. Since our compact bearing is a closed assembly, you only have to order and store one article which you then install in one simple movement.

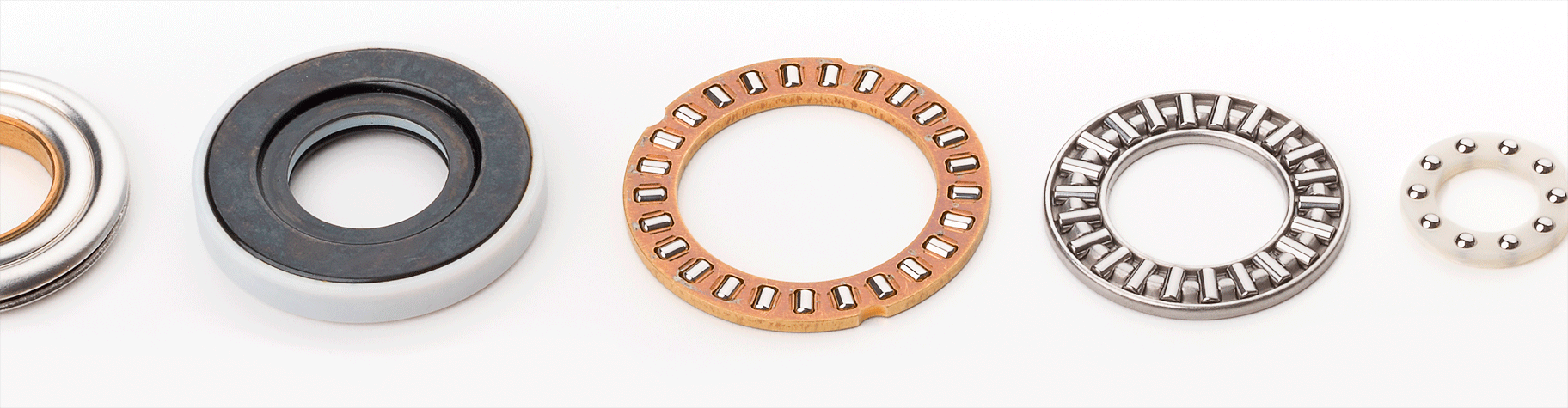

Components

Components such as ball cages, ribbon and snap cages, shaft and housing washers, as well as axial needle roller bearings can also be bought separately. They are available in various materials, such as brass, plastic, 100CR6 steel, or stainless steel.

We specialize in custom thrust bearings, but you can still find a selection of our standard products in our B2B Online Shop.

For you, this means maximum flexibility

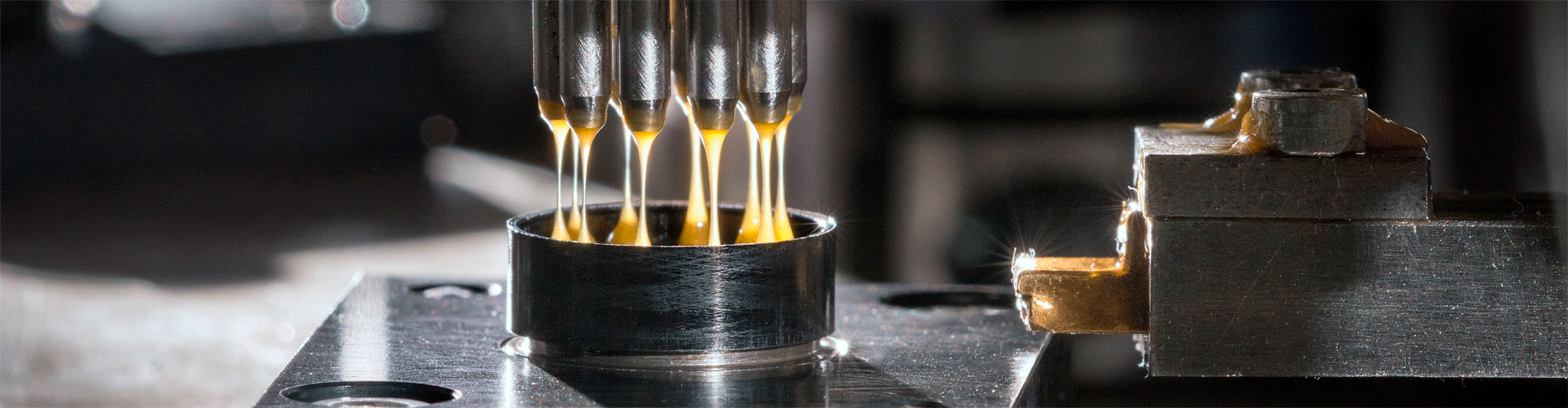

We can produce a variety of bearings at the same time. Also, we are very flexible – in the truest sense of the word - as far as production capacity is concerned. Depending on geometries and quantities, we can produce either on semi-automatic or on fully automatic machines.

With us, you get everything from one source

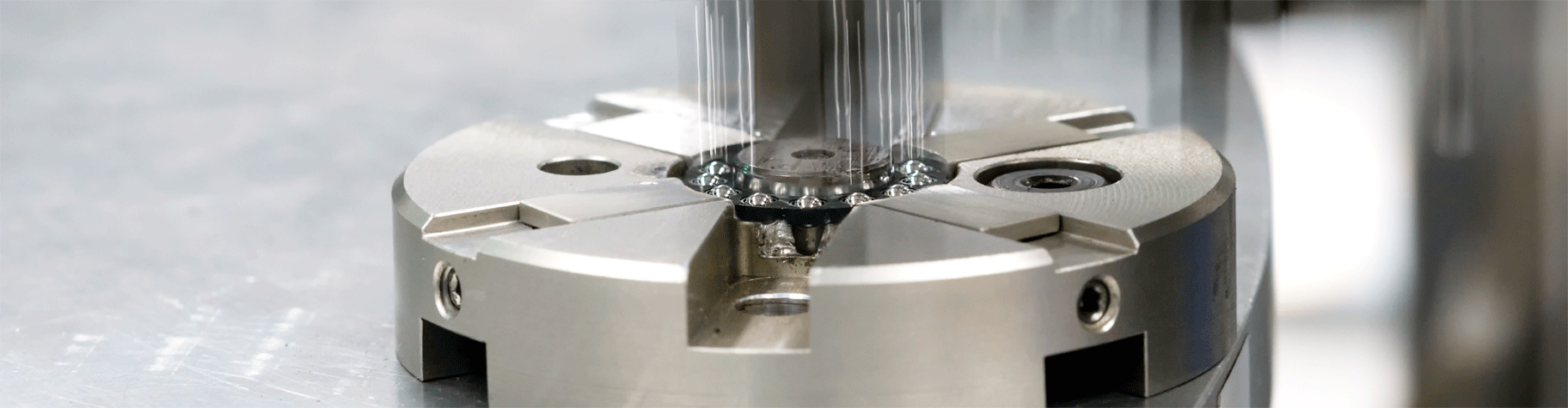

Of course, we fully comply with all specifications. Whatever the circumstances or industry, we strive for zero defects and therefore guarantee a comprehensive inspection of the finished products, the produced components, and their lubrication. Including a certification mark.

We'd love to hear from you

so we can find the best solution for you