Active Roster

Media

Sponsors

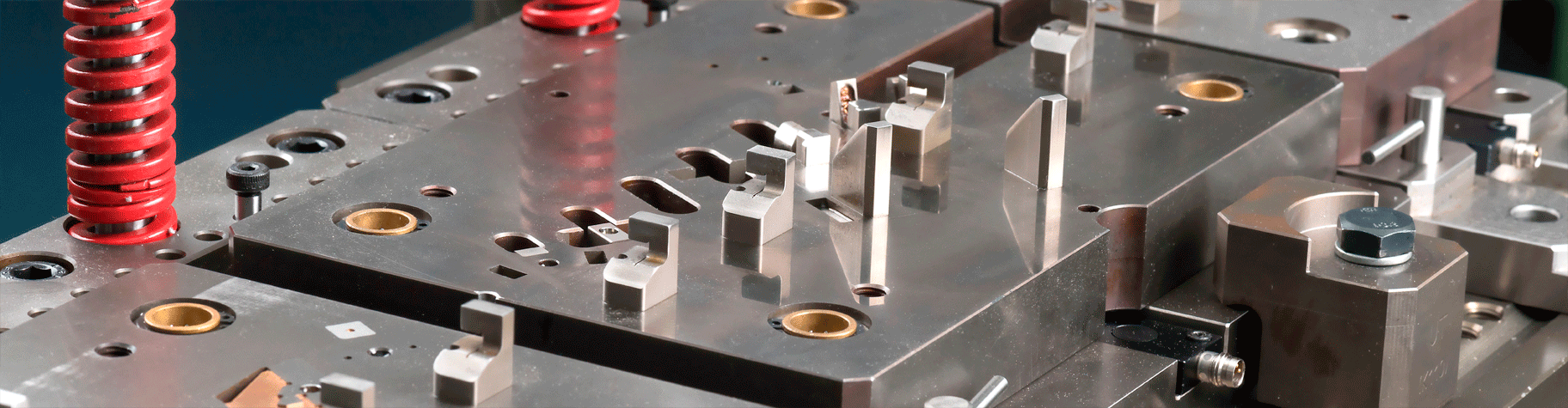

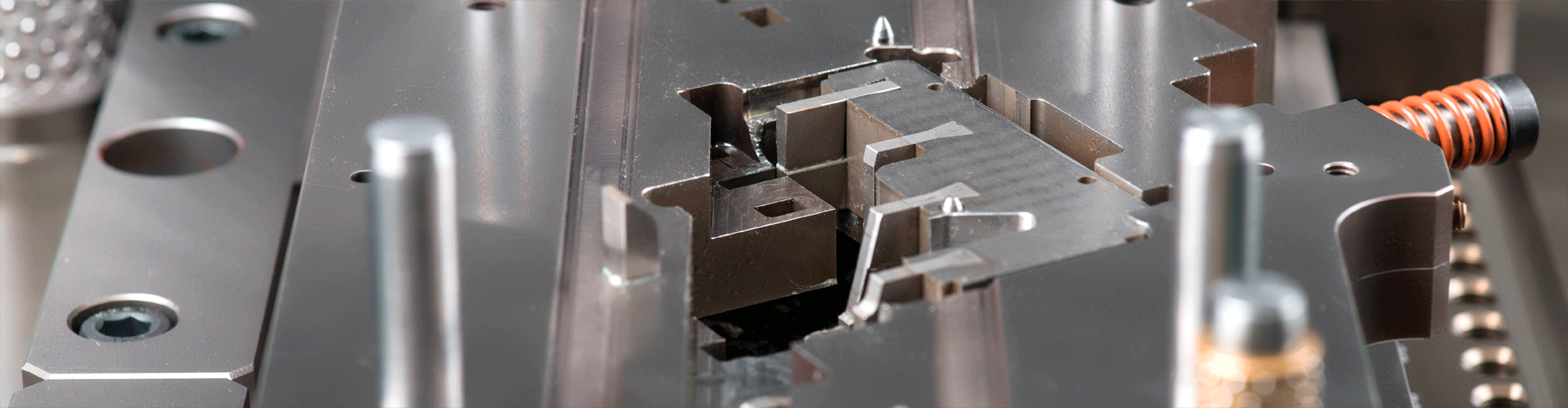

Toolmaking is the key to flexibility and reactivity

We develop custom progressive stamping and compound stamping tools, modular tools, as well as plastic injection molds for our plastics department.

Our in-house production of the tools enables us a high degree of reactivity in series production. This also provides a maximum number of variants and flexibility that are ideally suited to the stamping or plastic injection process.

Highest standards

Most of the tools we produce are built to order. To meet the high standards set by our customers and to cope with the series production quantities planned, our tools go through many different production steps.

Precision and high quality are always the top priority. Thanks to CAD/CAM, communication between our engineering and tooling specialists is efficient and paperless.

We are happy to accompany you through every phase of your project, and even samples close to series production can be produced in a flexible and timely manner. Our engineering service can support you in the design of your project at a very early stage of the planning process.

Tool care and maintenance

We take tool care and maintenance very seriously: careful storage in a fire-protected area and intelligent maintenance ensure that quality remains consistent.

We'd love to hear from you

so we can find the best solution for you